- About us

- Our products

- ECM - Vibro

- ECM - Plus

- ECM - Handy

- LDD 100

- ECM - Static

- NEW! ECM - CBR

- ECM - Vibrometer

- ECM - Vibrotester

- Our services

- Contact us

- česky

ECM-Vibro

It ensures quality while saving the costs. A system for continuous non-destructive measuring of compaction of soil during the works.

The aim of the compaction process is to achieve the required degree of compaction of the construction area in the shortest possible time and with the lowest possible cost. An essential part of this work is the measurement and the verification of the achieved compaction of materials. It is obvious, considering the necessary time and costs, that most methods of compaction measurement commonly used on building sites are time and costs consuming and thus of a little effect. In addition, the main disadvantage of these methods is their local character of measurement. For this reason, they do not give information about compaction of the whole area and therefore do not provide a guarantee that all insufficiently compacted spots will be detected. Most sophisticated solution according last standards BS 1377 or ZTVE StB 94 is compactometric system ECM - Vibro

- What is the system ELECTRONIC COMPACTION METER

- Why choose the system ELECTRONIC COMPACTION METER

- How works the system ELECTRONIC COMPACTION METER

- Capabilities of the system ELECTRONIC COMPACTION METER

- How to use ELECTRONIC COMPACTION METER system in praxis

- Review of significant features of the system ECM - Vibro

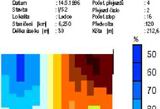

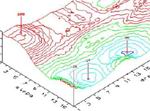

- Graphics displaying and data documentation unit GD3U-2000

What is the system ELECTRONIC COMPACTION METER

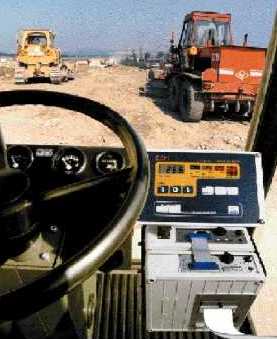

ELECTRONIC COMPACTION METER (ECM - Vibro compactometer) is a device for the verification and documentation of the state of compaction. This system represents a brand new quality in this field. The system is designed for installation on the vibratory compaction roller and allows measurement of the state of compaction of loose material directly during the work of the roller and it also informs instantly the operator about the state of compaction. In addition, a complete system allows a registration and subsequent evaluation of all measured data including statistical and graphical outputs in various formats.

ECM-Vibro system

Why choose the system ELECTRONIC COMPACTION METER

The main advantage of the ECM system is first, the possibility to reduce the number of overpasses needed for the achievement of the required degree of compaction, which brings along distinct savings of time and cost. Another significant advantage is the "mapping" of the compaction of the whole surface. This means that no under-compacted spots can be overlooked which often happens when using the standard methods. Sophisticated laboratory and field tests and several years operational experience with more then 230 of installations all over the world have proved the extraordinary reliability of the ECM system on the vibratory roller under hard conditions. A patented method of measurement allows the achievement of highest user parameters of the device. The producer is constantly in touch with the system users and acquired experience is flexibly projected into the innovation and the extension of the use of the system.

Field tests

How works the system ELECTRONIC COMPACTION METER

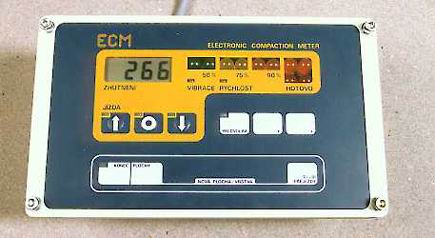

he basic version consists of three interconnected parts including a vibration sensor mounted on the non-turning part of the vibrating drum, a main processing unit and a console - keyboard and display unit. Two microcomputers contained within the central unit process a signal coming from the vibration sensor, and compute the state of compaction based on the changes of the sensor due to the interaction of the drum and compacted material. The console provides communication between the device and the operator. A large four-digit display and four colour control lights inform the operator about the current state of compaction, the achievement of the required value or indicate the point when compaction degree has ceased to increase which means the work can be finished. A variety of measurements of different types of loose material showed that there was a very tight correlation between the state of compaction indicated by the ECM system and the parameters of loose material measured by standard methods.

Console of ECM

Capabilities of the system ELECTRONIC COMPACTION METER

CM is truly a flexible system, which satisfies different demands. The non-expensive basic version provides a roller operator with instant information about the state of compaction. The fully equipped system provides an operator, as well as inspectors, with a high degree of comfort allowing them to make well-arranged documents on construction work quality. Another big advantage of this equipment is the possibility to expand the system gradually which spreads the costs of acquiring of the whole system over a longer period of time.

How to use ELECTRONIC COMPACTION METER system in praxis

Compaction to a required value

A value of the state of compaction, which represents a minimum requirement for the compaction of the area - so-called, preset value -, is stored in the system memory using this method. The value is determined by the compaction experiment on the same material, which will be used on the construction site. The rolling-over during the compaction has to go on until the pre-set value is achieved across the whole area which is indicated by a distinct red control light. Above all, the system indicates the achievement of 50%, 75% and 90% of the pre-set value.

Compaction to a maximum levelA certain type of the roller can be used for compaction of the layer of loose material only to a particular degree of compaction. The increase of compaction then stops and any further passes are ineffective and useless. In addition, an unwanted overcompaction of the layer can occur. The ECM system allows a measurement of the compaction increase between the two subsequent passes of the roller. The work is finished when the compaction has ceased to increase which is indicated by the flashing distinct red light. Thus a perfect compaction of the area can be achieved using a minimum number of passes without a risk of damaging the layer by overcompaction.

Review of significant features of the system ECM - Vibro

- Displaying the current value of the state of compaction (an average per 1 second)

- Indication of the achievement of required quality of compaction

- Displaying of the percentage of required value of compaction (50%, 75%, 90%, 100%)

- Indication of the state when compaction has ceased to increase

- Evaluation of the average value of compaction of the complete overpass as well as the whole area

- Evaluation of the increase of compaction between two subsequent overpasses

- Measurement of the frequency of the roller vibrations

- Check of the frequency of the vibrations during the measurement (Option)

- Check of the pre-set speed of the roller during the measurement (Option)

- Output for a printer - using a standard interface CENTRONICS

- Robust thermo-printer MiniPrint (Option) designed for direct installation inside the vibration roller allows printing of all measured data including text reports containing an order line number, a preset value, an average value of the whole line as well as area, an increase of compaction between two subsequent overpasses

- - Possibility of numerical and graphical prints using a PC; a built-in graphic processor (Option) allows a graphical print of the compaction process during the measurement - simulation of a line plotter - One roll of paper is sufficient for 24 hours of continuous printing

- Output for a computer - a standard serial interface RS-232C

- Output for an analogue device (plotter, tape recorder) (Option)

- Memory with a back-up for storing the measured data of 4 000 m2 (standard) up to 100 000 m2 (Option) of compacted area; data are kept in the memory even when the power is off

- Recorded data can be transferred into a computer directly or using a pocket memory unit ECM - Handy

- Software for transferring of measured data into a computer, creating of data files, viewing, printing, statistics as a standard graphical displaying (Option) in various formats, printing of protocols

- Design solution and produce technology ensure a maximum resistance against shocks and vibrations and thus a long working life and reliability of the system; checking and auto-testing features including built-in sources of the test signal

- On-line Built-in Graphical Data-processing Unit (GDU) with color LCD screen soon available